Welcome to HB Engineering, where we don't just manufacture spare parts, we deliver peace of mind for every vessel out at sea.

Founded in 2013 in the industrial city of Rajkot, India, HB Engineering has built its name on quality, trust, and performance. We specialize in high-quality aftermarket spare parts for marine air compressors and pumps, including pistons, valves, cylinder heads, cylinder blocks, and more. Every product is engineered with precision, tested for durability, and trusted by marine professionals worldwide.

Over the years, we’ve grown from a regional supplier into a global partner, trusted by ship operators, marine engineers, and fleet managers across the world. At HB Engineering, we don't just manufacture spare parts, we deliver reliability that keeps vessels moving, no matter how rough the seas.

Trusted air compressor parts built for durability under pressure.

Pump components designed to deliver consistent performance in every flow.

Manufacturing quality parts that power reliable and efficient refrigeration systems.

Durable parts designed to extend separator life and reduce downtime.

Building filtration components that protect systems and boost efficiency.

Providing leak-proof sealing solutions for smooth, uninterrupted operations.

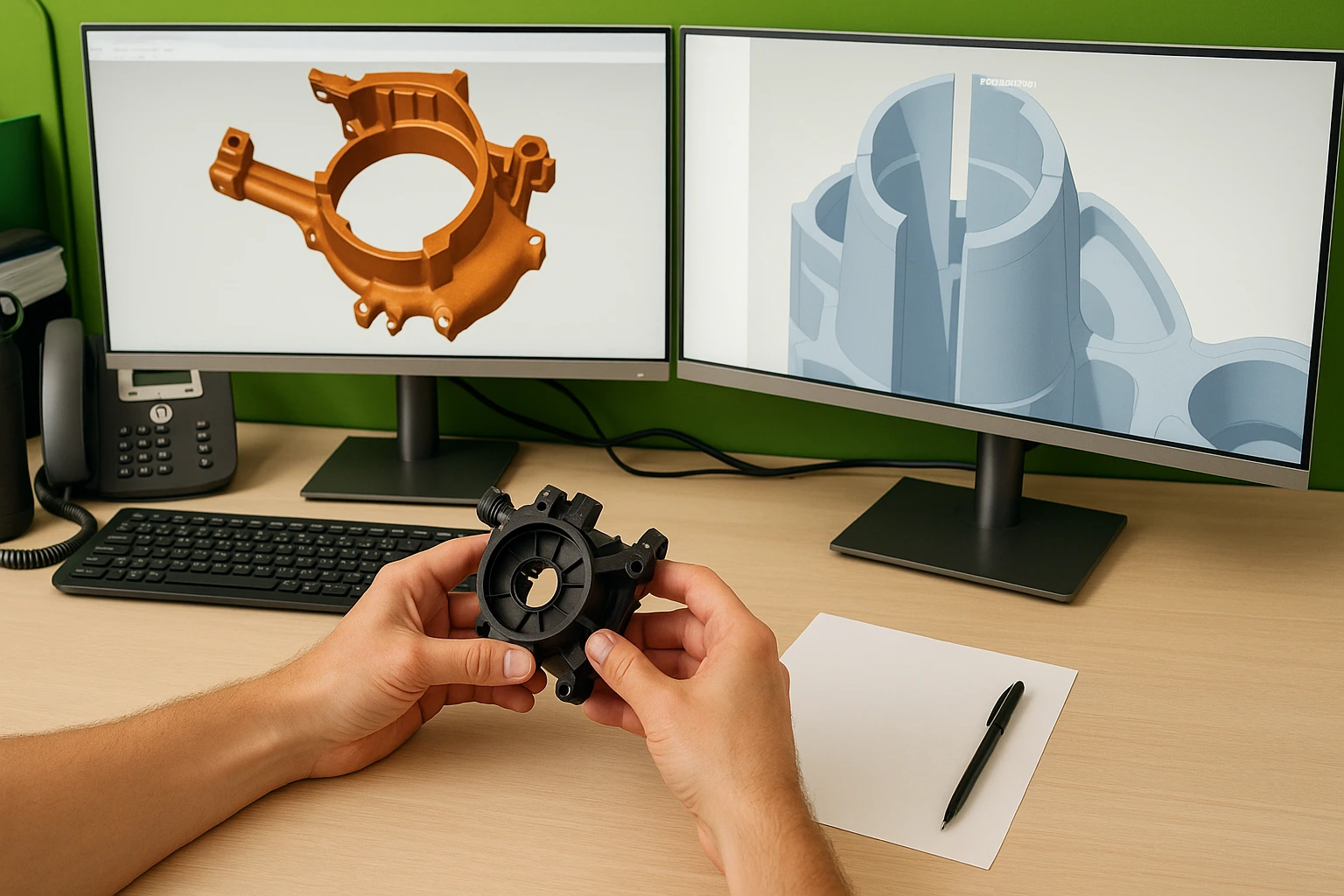

Our journey begins in the digital realm with high-precision 2D and 3D modeling. Using advanced CAD (Computer-Aided Design) software, we meticulously define every geometric contour and critical dimension of each component.

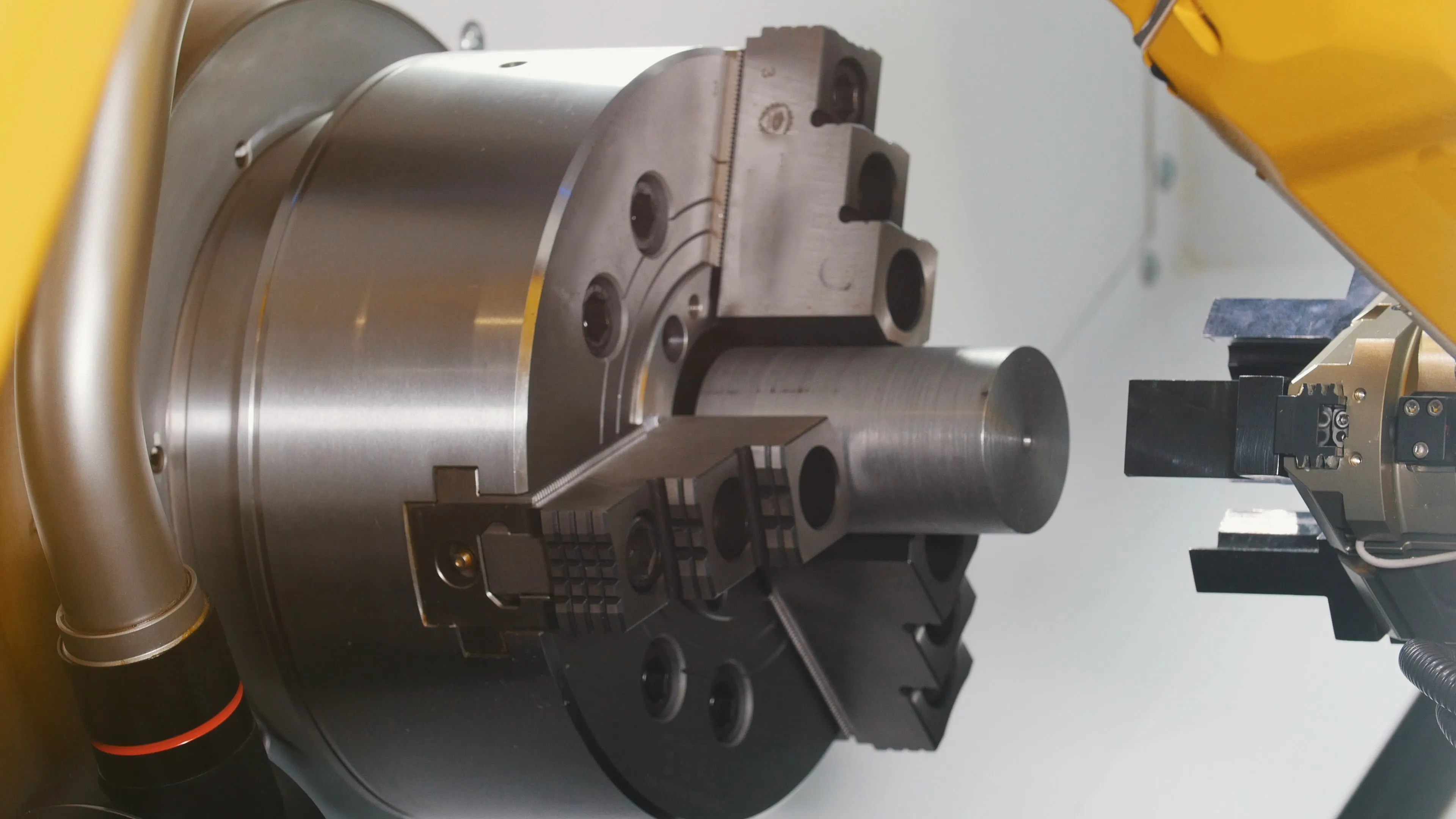

Our skilled engineers transform CAD models into production-ready instructions using advanced CAM (Computer-Aided Manufacturing) software. By optimizing toolpaths and simulating real-world conditions, we generate precise G-code that drives our CNC VMC machines. This process ensures every part is machined with exceptional accuracy, minimal waste, and maximum efficiency.

Before the first chip falls, we prepare raw materials with precision and care. Each component is securely mounted on the VMC bed using custom-built fixtures or vises tailored to its geometry. Our team then calibrates tools, aligns references, and performs zero-setting operations to ensure machining begins from the exact position-because true precision starts with the setup.

With everything in place, our Vertical Machining Centers (VMC) spring to life. From intricate milling and precision drilling to tapping and pocketing, our CNC machines operate with micron-level accuracy. High-speed spindles, rigid tooling, and intelligent control systems work together to achieve tight tolerances and flawless surface finishes-every single time.

As machining progresses, our team conducts continuous inspections using micrometers, dial indicators, and probing systems. Key dimensions are verified in real time, allowing us to detect and correct any deviation at the earliest stage. This meticulous approach ensures that every part not only meets but often exceeds the required specifications-before it ever leaves the machine bed.

After machining, each part undergoes a final stage of detailed finishing and rigorous quality checks. Burrs are removed, edges are smoothed, and surface treatments are applied as required to meet both functional and aesthetic standards. Our QC team inspects every component against strict benchmarks to ensure it is production-ready, dependable, and built to perform under the toughest marine conditions.

Once each component passes our rigorous quality checks, it advances to the final stage-secure packaging. We use durable, moisture-resistant materials along with custom protective layers to safeguard parts during transit. Every package is clearly labeled with complete identification details, ensuring safe handling, easy tracking, and reliable delivery to clients worldwide.

Our CNC and VMC machines deliver high-quality parts with consistent accuracy and efficiency, meeting the strictest technical standards.

High tolerance parts with consistency, accuracy, and efficiency, meeting the strictest technical standards every time.

Time is money, especially at sea. Our streamlined production and ready-to-ship inventory help minimize downtime and keep your operations moving.

Every ship, every system is unique. That’s why we tailor our components to your exact specs, delivering solutions engineered for your most complex challenges.

We don’t just check, we verify. Each part undergoes strict multi-stage inspections to ensure top tier reliability and long term performance.

From port to port, we deliver. Our trusted logistics network ensures safe, on-time delivery no matter where in the world your operations are based.